NAVIGATION

SOCIAL

ADDRESS

Unit 4a, Enigma Centre

Bilton Road

Bletchley,

Milton Keynes

MK1 1HW

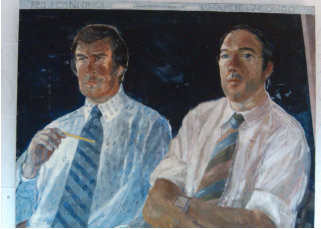

KP PLASTIC INJECTION MOULDING business was started by Reg

Cannings and Charles Congo in the 1960’s and is still family run by

Simon Cannings and Zoe Congo. NEW PREMISES were bought in

2005 to expand floor space and productivity. Since then we have

MODERNISED our TOOLROOM and added to our range and

capacity of moulding machines.

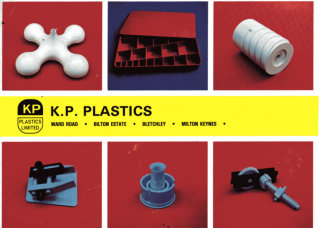

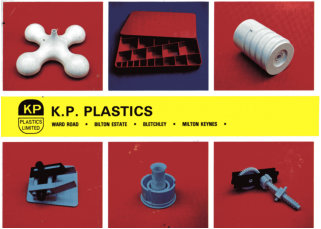

We manufacture products from a few grams in shot weight up to

almost 2kg with over 20 MOULDING MACHINES, including vertical

moulding machines for specialist insert jobs.

ABOUT

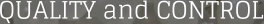

KP Plastics since 1960KP PLASTICS

Our HistorySERVICES

TOOLROOM, DESIGN, PLASTIC MOUDINGS, ASSEMBLY

With our years of experience we ensure the transition from design

stage to finished plastic part is as smooth as possible.

Please send us your designs, as CAD, 2D sketches, or simply talk us

through your requirements.

Allow us to advise the best route to make your product efficiently

and cost effectively.

If required, parts can be 3D Printed thereby viewing prototypes

before commiting to final tooling.

TOOLING IS PRODUCED AT OUR UK SITE which ensures full control

and best practise. This means any tooling modifications and all tool

maintance can be is easily completed.

The RANGE OF POLYMERS available is ever growing, and we are

happy to liase with you to achieve the right plastic for the correct

application.

The FINISH and COLOUR can then be determined: the choice is

yours.

Once your product is manufactured we can assemble, weld,

package and print to your requirements.

Plastic products, when designed correctly are long lasting, cost effective and 100% recyclable.

- KP PLASTICS GREEN CREDENTIALS

The beginning is the most important part of the work.

- PLATO

LET KP PLASTICS GET THE JOB RIGHT

FROM START TO FINISH!

We listen to your requirements and get the job done to your high standards.

- KP PLASTICS

KP Plastics began in 1960

Reg and Charlie started KP Plastics in what was soon to become the heart of Milton Keynes industry. Centrally located with direct routes throughout the UK the company grew.

1970’s to 2000

New plastics and processes meant KP was continually helping develop new projects. Our mouldings are in sectors as diverse as toys and cosmetic cases to agriculture and power plants.

21st Century move

In 2005 KP moved to new larger premises which meant all facilities were under one roof, streamling production and tool making.

Large Range of Machines

KP has over 20 plastic injection moulding machines from 30 tonnes to 600 tonnes, which means we can produce a wide range of plastic parts, from lightweight gram to 2kg mouldings.

Heavy Lifting

Our 5 tonne gantry means we have expanded the range of tools we can mould as we can lift 5000kg as required.

KP Toolroom

Our in house toolroom and CAD means we can produce injection moulding tools cost effectively and ensure quality and common sense is at the front of every tool we produce for you. UK manufacture with KP means total control of your finished product. You can easily liase with us at each stage.

Phone:

01908 630030

COPYRIGHT KP PLASTICS

NAVIGATION

SOCIAL

ABOUT

KP Plastics since 1960

KP PLASTIC INJECTION MOULDING

business was started by Reg Cannings and

Charles Congo in the 1960’s and is still

family run by Simon Cannings and Zoe

Congo. NEW PREMISES were bought in

2005 to expand floor space and

productivity. Since then we have

MODERNISED our TOOLROOM and added

to our range and capacity of moulding

machines.

We manufacture products from a few

grams in shot weight up to almost 2kg with

over 20 MOULDING MACHINES, including

vertical moulding machines for specialist

insert jobs.

With our years of experience we ensure the

transition from design stage to finished

plastic part is as smooth as possible.

Please send us your designs, as CAD, 2D

sketches, or simply talk us through your

requirements.

Allow us to advise the best route to make

your product efficiently and cost effectively.

If required, parts can be 3D Printed thereby

viewing prototypes before commiting to

final tooling.

TOOLING IS PRODUCED AT OUR UK SITE

which ensures full control and best

practise. This means any tooling

modifications and all tool maintance can be

is easily completed.

The RANGE OF POLYMERS available is ever

growing, and we are happy to liase with

you to achieve the right plastic for the

correct application.

The FINISH and COLOUR can then be

determined: the choice is yours.

Once your product is manufactured we can

assemble, weld, package and print to your

requirements.

SERVICES

TOOLROOM, DESIGN, PLASTIC MOUDINGS, ASSEMBLY

KP PLASTICS

Our History

Plastic products, when designed

correctly are long lasting, cost

effective and 100% recyclable.

- KP PLASTICS GREEN CREDENTIALS

The beginning is the most

important part of the work.

- PLATO

LET KP PLASTICS GET THE JOB RIGHT

FROM START TO FINISH!

We listen to your requirements

and get the job done to your high

standards.

- KP PLASTICS

KP Plastics began in 1960

Reg and Charlie started KP Plastics in what was soon to become the heart of Milton Keynes industry. Centrally located with direct routes throughout the UK the company grew.

1970’s to 2000

New plastics and processes meant KP was continually helping develop new projects. Our mouldings are in sectors as diverse as toys and cosmetic cases to agriculture and power plants.

21st Century move

In 2005 KP moved to new larger premises which meant all facilities were under one roof, streamling production and tool making.

Large Range of Machines

KP has over 20 plastic injection moulding machines from 30 tonnes to 600 tonnes, which means we can produce a wide range of plastic parts, from lightweight gram to 2kg mouldings.

Heavy Lifting

Our 5 tonne gantry means we have expanded the range of tools we can mould as we can lift 5000kg as required.

KP Toolroom

Our in house toolroom and CAD means we can produce injection moulding tools cost effectively and ensure quality and common sense is at the front of every tool we produce for you. UK manufacture with KP means total control of your finished product. You can easily liase with us at each stage.

ADDRESS

KP Plastics UK Ltd

Unit 4a, Enigma Centre

Bilton Road,

Bletchley,

Milton Keynes

MK1 1HW

COPYRIGHT KP PLASTICS 2019 - 2020

Phone:

01908 630030